Are you giving your multi-needle machine the tender loving care it deserves? Every day, before revving that baby up, slip one drop of oil into the hook. It takes less than a minute and is worth every second. A well-oiled machine is a high-performing machine.

Here’s how to do it. First, remove the bobbin case. Clean all fibers out of the bobbin case and hook area. I bend the end of a pipe cleaner about 2” from its sharp pointy end and use it to clean my machines. It gets in all the nooks and crannies with snagging or scratching any metal parts. Clean the inside of the hook area.

Swipe around the hook.

Place a drop of oil into the hook and replace the bobbin case.

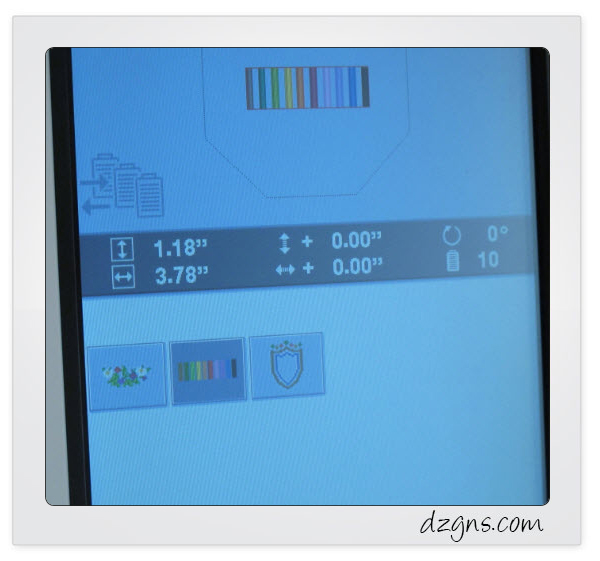

Every once in a blue moon – okay 40-50 hours of sewing time, drop a dollop of oil on each needle bar. How do you know how many hours you’ve stitched? This machine is so smart it keeps a record. Go to Notes, page 6 and read the information. You’ll find the stitch count – the stitches from the beginning of time, the stitches since your last dealer maintenance and the hours from the beginning of time and since your last maintenance. My machine is just six hours short of needing another drop of oil on each needle bar so I’ll go ahead and do it now.

Close the Notes screen and touch the Needle bar icon.

I’ve already oiled the first needle bar so I’ll select needle 2.

Place your finger on foot 2 and pull it down to expose the felt washer above the needle bar. Add a drop of oil to the felt washer. Repeat for all 10 needles.

Now, do yourself a favor and stitch a test design. Go to the main page and touch the first design icon.

Select the 10 bar design.

Stitch the design.

Inspect the wrong side of the embroidery to check the tensions.

Next week, we’ll clean the upper thread path.

13 COMMENTS

Joe

11 years agoVery, very helpful for me to learn about my multi needle machine. Thanks to Eileen for all the great advice.

Carolyn Rollberg

11 years agoThanks for the reminder to oil the o

Pads on the needle bar!

claudia hermansen (Create with Claudia)

11 years agothank you so very much! I also take the plastic cover off of the entire machine and lube and oil all moving parts (shown to me by my wonderful service man). I had a rusty bearing that would freeze up and cause design misalignement after 15000 stitches due to the hoop slippage from the frozen bearing. You can get the machine oil from Ace Hardware as well as White Lithium grease for this purpose.

claudia hermansen (Create with Claudia)

11 years agoIs there a way to selcet all, copy and paste with the pictures? I just got the printed part when doing that to MS Word.

Rita Wahl

11 years agoThank you so much for this timely tip about the oiling. I just got a used PR600 on Saturday & there is a note taped to the front saying to oil it daily before stitching. I was skeptical as I don’t have to do that with other embroidery single needle machines. Every day now, I will!

cathy sutton

11 years agothanks for the reminder on taking care of our machines. cathy

Kay

11 years agoHey Guys and Girls!

I adore Eileen’s blog. No matter how many times you do something, reminders are an asset because 1 time you might not do the norm. Speaking of oiling…I am a stickler. When I teach people how to use their new multi-needle machines, first thing I always stress…OIL! Never start your machine unless it has been oiled that day. The very first thing I do when I get up is oil my machines, leaving the doors to the bobbins open so I will not forget that I have done this especially if I have a busy day. Then I put an almost used up bobbin in the bobbin case and slip it into the machine to absorb any extra oil. This will be a life-saver, especially if your first project is something machine oil will ruin. Trust me, sometime, that oil will bleed through to your first project and what a mess! That almost used -up cardboard bobbin is great insurance.

Bonnie

10 years agoThanks for the idea of using an almost used up bobbin as I have wondered how to prevent oil getting on projects as I had that happen before!

sammi

11 years ago@Claudia: When pasting to MS Word, click the icon on the far left that says “keep source formatting”. It has a paint brush icon on it.

Carolyn

11 years agoWhen I bought my used PR600II, I was told oiling the hook everyday was the single most important task to the machine’s life. Cleaning the hook and bobbin area everyday was 2nd. I use a needle-tip oiler. It is perfect to get just a drop of oil in the right spot.

Luci Slywka

11 years agoGreat illustrations. Better than the instruction manual. Thanks for the needle oiling information that is not in the manual.

presentation binders

10 years agoAn impressive share, I simply given this onto a colleague who was doing somewhat evaluation on this. And he the truth is bought me breakfast because I discovered it for him.. smile. So let me reword that: Thnx for the deal with! But yeah Thnkx for spending the time to debate this, I feel strongly about it and love reading extra on this topic. If possible, as you change into experience, would you thoughts updating your weblog with extra details? It is highly helpful for me. Big thumb up for this weblog publish!

red spots on skin not itchy

10 years agoI would like to show my appreciation for your kindness giving support to people that really want help on this particular issue. Your real commitment to getting the message all through appeared to be exceedingly informative and has continually made employees much like me to achieve their desired goals. Your informative hints and tips means a lot to me and far more to my mates. Best wishes; from everyone of us.